Manufacturing tea is an art, it’s poetry in motion, it’s farmer-chef-craftsman-mechanic-chemist, all melded together. A few weeks ago, I did it in a conference room in Atlanta, GA. And "they" were right, even trying this was crazy... but, son-of-a-gun, the teas actually turned out pretty good. You can come to TeaSource Eden Prairie on Sunday, December 8th from Noon-2p and taste them for yourself!

In late October, I co-presented a workshop to tea professionals at the World Tea East Exhibition in Atlanta, GA. This workshop was called Processing Tea: An Experiential Workshop. The idea was we would fly in just plucked tea leaves from Hawaii by Overnight Air. Then over the two days of the workshop, using these fresh tea leaves we (along with the class attendees) would manufacture: white, green, yellow, oolong, and black tea. I presented this class with Donna Fellman of the World Tea Academy (part of World Tea Media). Donna and World Tea Media deserve tremendous credit for taking a huge chance, putting up the cash necessary, and providing all the support possible. Donna is one of the world’s great tea educators. For the record, this was the third time we did this class. In this blog, over the next few posts, I am going to tell the story of what happened. In Hawaii, Eva Stone, proprietor of Tea Hawaii & Co., supplied us with fresh plucked tea leaves.

The tea fields and the home of Tea Hawaii & Co.

Based on experience, Donna has developed a system of packing and layering and insulating the tea leaves using dry ice and coolers: so that when we unpacked the tea leaves in Atlanta, they looked like they had been plucked off the bush about three hours before.

Donna Fellman, unpacking and sorting the just arrived tea leaves.

Take a look at those leaves. This is what tea leaves look like, a few hours after being plucked. A relatively small amount of withering has taken place, so the leaf gets kind of floppy (I try to avoid the word flaccid). This also happens as the leaves come in from the fields to the factories. In our case, the withering took place on the FedEx plane ride, but this withering was slowed down considerably by the packing and dry ice. The leaves arrived pretty much ready for the first step in manufacture.

During two, three-hour workshops, over each of the next two days, we were going to try to mimic what happens at a tea factory, as the freshly plucked tea leaves are brought in from the field. By definition, this is kinda crazy. We weren’t in a tea factory—we were in a conference room at a convention center. We were going to try to make five different types of tea: all in the same room, at the same time. We didn’t have any of the equipment available at a tea factory. The climate was totally wrong and uncontrollable (we were battling hotel-level air conditioning). And most importantly we are NOT tea manufacturing experts. Donna’s a great communicator, and I’m just a tea merchant. They were right, this was crazy—who the heck did we think we were ??? But we were determined to try and manufacture by hand all categories of tea: except for Dark Tea & Puer --- I admit it, we chickened out on this --- maybe next year. And not only were we going to manufacture these teas, we were also going to demonstrate and teach others how these teas are processed.

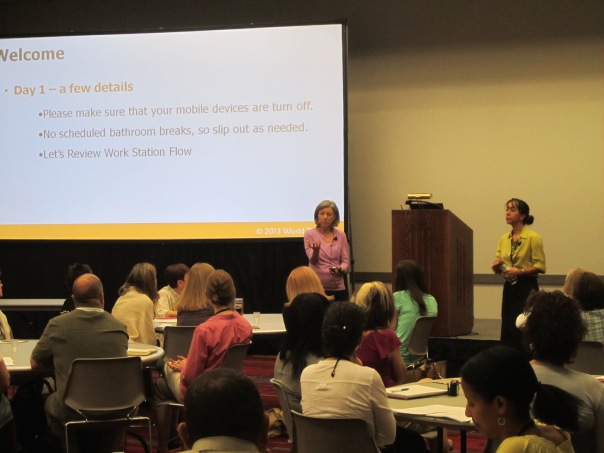

Donna and Eva, kicking off the class.

Over the next few posts I will show and tell details about processing all five of these teas. The bottom line is, the class worked. And on Sunday, December 8th from Noon until 2:00pm at our Eden Prairie TeaSource we will be steeping and sampling all five of these teas we made. I should note there is not much of each tea, so when we run out (and we will) that’s it. This is almost a once in a lifetime experience, especially if you are unlikely to ever visit an actual tea estate.

Also, I will be there just to talk about tea, answer tea questions, and chat about all things camellia sinensis. Stop by if you get the chance.

-Bill Waddington